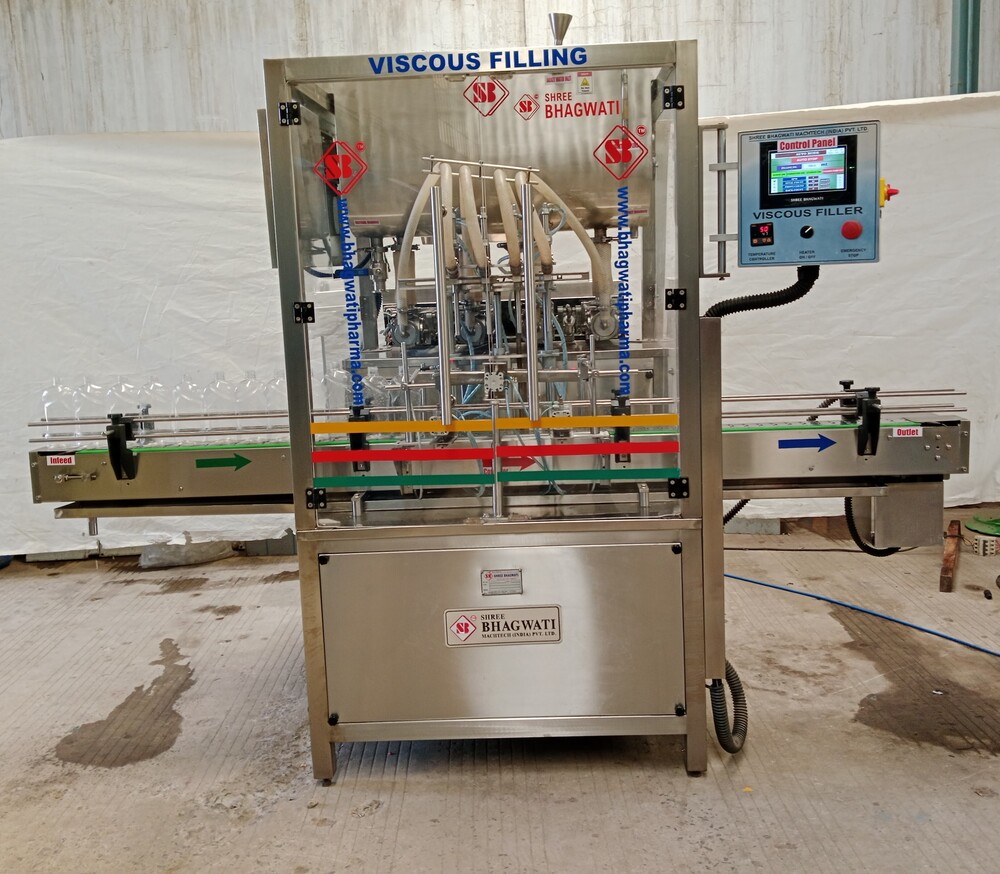

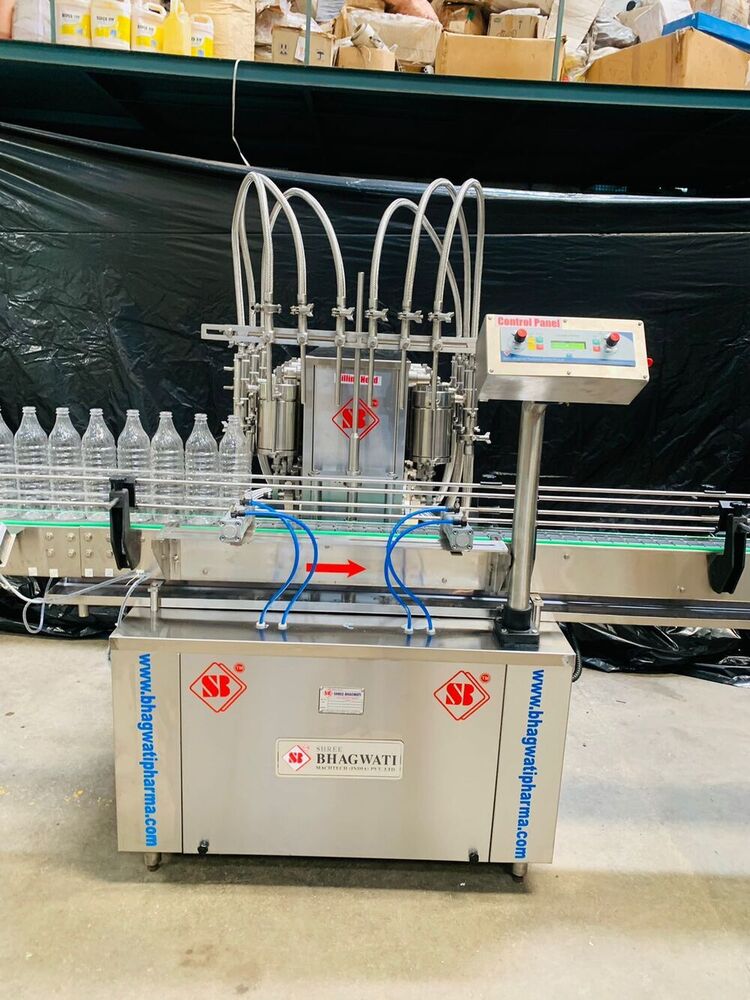

Automatic Rotary Piston Filling Machine

Product Details:

Automatic Rotary Piston Filling Machine Price And Quantity

- 1500000 INR/Unit

- 1 Unit

Automatic Rotary Piston Filling Machine Trade Information

- 30 Unit Per Month

- 8 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Packing Only

- Australia, Middle East, Western Europe, Central America, Africa, South America, Asia, Eastern Europe, North America

- All India

- CE & ISO Certified

Product Description

Automatic Rotary Piston Filling & Capping Machine

![]() Key Features:

Key Features:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Depends on fill size/ nature & viscosity of liquid We can supply as per client„s requirement with the help of change parts |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Gravity filling system is simplest and efficient filling system for non carbonated liquids, like vacuum filters, these fillers also maintain same level while filling particular size adjustment and fill by gravity principle. It is used for filling only non carbonated liquids. Gravity fillers are available in options of with and without partial vacuum depending upon applications. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Vacuum filler is a rotary level filler which fills with vacuum principle and maintains same level while filling particular size adjustment. It is used for filling only non carbonated liquids. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| To fill-liquor, pharma liquids, household liquids in glass rigid bottles and containers. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS