Automatic Packaging Machine |

Monoblock Single Head Mosquito Repellent Filling and Capping Machine

- Supply Ability:30 Per Week

- Delivery Time:4 to 6 Week

- Control System:PLC Control

- Power:As per the client required Watt (w)

- Type:Packaging Line

- Feature:Beverage, Chemical, Food, Medical, Apparel, Other

- Computerized:Yes

- Drive Type:Electric

- Material:Stainless steel

- Automatic Grade:Automatic

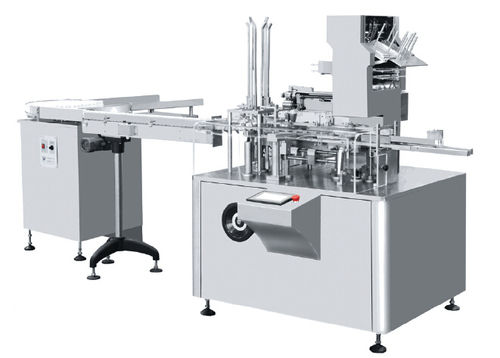

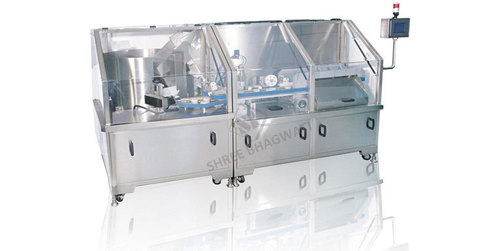

Automatic Cartooning Machine

- Color:stainless steel

- Capacity:As per the Client required Kg/hr

- Dimension (L*W*H):In inches Inch (in)

- Weight (kg):In kgs Kilograms (kg)

- Power:As per the client required Watt (w)

- Type:Pharmaceutical Packaging Machine

- Voltage:As per the client required Volt (v)

- Warranty:1 year

- Supply Ability:30 Per Week

- Delivery Time:13-15 Week

Leak Detector

Single Head Leak Detector is a PLC based machine, used to test bottle/container for pin holes and proper shaved neck in molded bottles/containers. Leak detectors validate your molded bottles/containers for further Filling & Sealing operations.

Collection Table

Scramblers & UN -Scramblers size 36" diameter, with variable pitch pulley drives, to ensure uniform flow of Glass Containers to suit different machines and purpose on line.

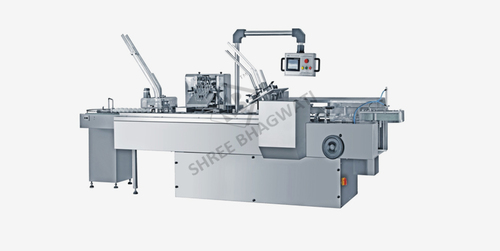

Bottle Cartoning Machine

- Supply Ability:30 Per Week

- Delivery Time:8-10 Week

- Warranty:1 year

- Voltage:As per the client required Volt (v)

- Control Mode:Automatic

- Material:Stainless steel

- Computerized:Yes

- Capacity:As per the Client required Kg/hr

- Color:stainless steel

- Dimension (L*W*H):In inches Inch (in)

Cartooning Machine Bottle

- Supply Ability:30 Per Week

- Delivery Time:10-12 Week

- Capacity:As per the Client required Kg/hr

- Color:stainless steel

- Dimension (L*W*H):In inches Inch (in)

- Power:As per the client required Watt (w)

- Weight (kg):In kgs Kilograms (kg)

- Type:Other

- Voltage:As per the client required Volt (v)

- Warranty:1 year

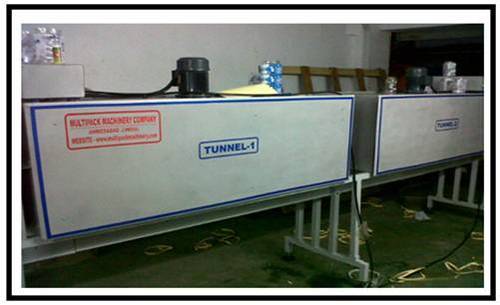

Shrink Tunnel Machine With Conveyor

- Supply Ability:30 Per Week

- Delivery Time:4 Week

- Material:Stainless steel

- Computerized:No

- Control Mode:Semi-Automatic

- Power:As per the client required Watt (w)

- Voltage:As per the client required Watt (w)

- Warranty:1 year

Automatic Tablet/ Capsule Filling Machine

Tablet counting and filling machine adopts advanced vibration and multi-Track delivery chute with PLC control, transfer the Container automatically, system test automatically. The machine With Stop automatically function and other advanced technology. This machine designed with GMP standard. Compose the light, electric machinery to one set, which is suitable for Tablet counting and filling in pharmaceutical or food business. The equipment runs reliably. It is easy to change the specification of Container. Control system of the machine can store working parameter of various medicaments. Good man-machine work interface makes operators master easily. The machine conforms to requirements of GMP Standards.

Automatic Vial Filling Machine

Automatic Vial Filling & Stoppering Machine is suitable to fill injectable glass vials. The basic unit consists of turntable, Stainless Steel Stat conveyor belt, unique eccentric pre-gassing, filling and post-gassing. Highly efficient and precision built Stainless Steel 316L Syringes, non- toxic synthetic rubber tubing and easy reach compact panel. The minimal distance between filling and stoppering units reduces the risk of contamination. The machines are designed for operation in a sterile area and for use under laminar flow protection. The un-scrambler itself has been redesigned to eliminate dead ends and difficult-to-clean spots.

Vial Filling and Cap Sealing Machine

Automatic Vial Flling Rubber Stoppering and Cap Sealing Machine is a compact model use for filling, rubber stoppering and cap sealing of injectable liquid vials. This compact machine is also called combi vial filling stoppering and sealing machine as all three process take place on single platform. Machine is ideal choice for small but online tunnel based filling line operations.

Fully Automatic Shrink Sleeve Label Applicator Machine

- Delivery Time:4-6 Week

- Weight (kg):In kgs Kilograms (kg)

- Dimension (L*W*H):In inches Inch (in)

- Power:As per the client required Volt (v)

- Type:Other

- Color:Stainless Steel Finished

- Capacity:Up to 7000-10000-BPH Kg/hr

- Control Mode:Automatic

- Computerized:Yes

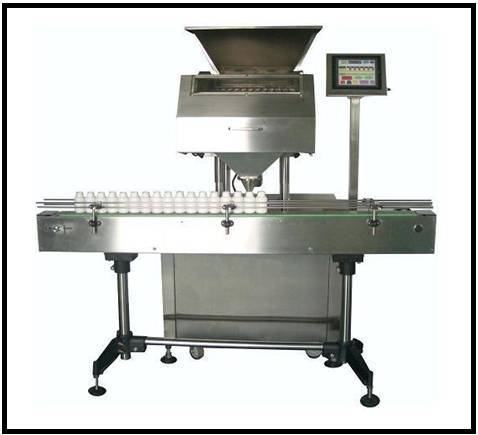

Electronic Type Tablet Counting Filling Machine

The Counter will fulfill all your needs of tablet counting and filling. It enables every possibility.! 100% counting accuracy guaranteed. Having highly speed Counting quantity can be set from 3pieces to 30000pieces per bottle. The design of heavy duty stainless steel with polished welds on all horizontal surfaces prevents dust building up in operation. Seamless design prevents potential product contamination. This machine is equipped with advanced detecting system including of a dust compensator and bulit-in spike controller. The sensor adjusts its sensitivity automatically to offset the gradual accumulation of "dust" on the sensor window. Product contact materials are all made of 316,304 Stainless Steel or PE. Auto rejection system removes incorrectly-filled containers off the conveyor and resets the correct counting amount. This machine is programmable to stop immediately when containers are incorrectly filled.

Capsule Inspection Polishing Machine

- Voltage:As per the client required Watt (w)

- Warranty:1 year

- Material:Stainless steel

- Computerized:Yes

- Control Mode:Automatic

- Color:stainless steel

- Capacity:As per the Client required Kg/hr

- Dimension (L*W*H):In inches Inch (in)

- Supply Ability:30 Per Week

- Delivery Time:4-6 Week

Tube filling machine

Shree Bhagwati (1996) is a leader in manufacturing machinery for chemical, pharmaceutical, cosmetic, ayurvedic and herbal industry.The machine is very simple to operate, it consists mainly, one rotating disc with interchangeable tube holding sockets for different size of tubes. Only empty tube should feed manually, after that all process like filling, closing, coding process is automatic.

Automatic Two Head Liquid Vial Filling with Rubber Stoppering Machine

SBLFRS Automatic Vial filling with Rubber Stoppering Machine is a compact model used for filling and rubber Stoppering of liquid into Vials.

Empty Capsule Uploading Machine

Our Empty Capsule Uploading Machine is Suitable for all sizes of capsules, highly versatile, Easy to operate, high capacity, and Low noise.

Automatic Capsule Filling Machine

- Supply Ability:30 Per Week

- Delivery Time:12-15 Week

- Warranty:1 year

- Voltage:As per the client required Volt (v)

- Control Mode:Automatic

- Material:Stainless steel

- Computerized:Yes

- Color:stainless steel

- Capacity:As per the Client required Kg/hr

- Weight (kg):Around 1400 kgs Kilograms (kg)

Automatic Electronic Type Tablet Counting Filling Machine

- Material:Stainless steel

- Computerized:Yes

- Control Mode:Automatic

- Warranty:1 year

- Voltage:As per the client required Volt (v)

- Weight (kg):In kgs Kilograms (kg)

- Dimension (L*W*H):In inches Inch (in)

- Power:As per the client required Watt (w)

- Supply Ability:30 Per Week

- Delivery Time:8-10 Week

Automatic High Speed tablet /capsule Counting Machine

- Delivery Time:6-8 Week

- Supply Ability:30 Per Week

- Color:stainless steel

- Capacity:As per the Client required Kg/hr

- Weight (kg):In kgs Kilograms (kg)

- Dimension (L*W*H):In inches Inch (in)

- Power:As per the client required Watt (w)

- Type:Capsule Filing Machine

- Warranty:1 year

- Voltage:As per the client required Volt (v)

Round Plate Type Tablet/Capsule Counting and Filling Machine

- Power:As per the client required Watt (w)

- Dimension (L*W*H):In inches Inch (in)

- Weight (kg):In kgs Kilograms (kg)

- Type:Capsule Filing Machine

- Color:stainless steel

- Computerized:Yes

- Material:Stainless steel

- Control Mode:Automatic

- Supply Ability:30 Per Week

- Delivery Time:4-6 Week

Automatic High Speed Unscrambler Machine

- Warranty:1 year

- Voltage:As per the client required Volt (v)

- Material:Stainless steel

- Computerized:Yes

- Control Mode:Automatic

- Capacity:As per the Client required Kg/hr

- Color:stainless steel

- Dimension (L*W*H):In inches Inch (in)

- Delivery Time:8-10 Week

- Supply Ability:30 Per Week

Turn Table Machine

- Supply Ability:30 Per Week

- Delivery Time:2-3 Week

- Warranty:1 year

- Voltage:220 Volt Volt (v)

- Computerized:Yes

- Material:Stainless steel

- Control Mode:Automatic

- Capacity:As per the Client required Kg/hr

- Color:stainless steel

- Weight (kg):In kgs Kilograms (kg)

Automatic Double Head Viscous Filling Machine

Automatic Viscous Filling Machine works on volumetric principle with rotary valve type piston. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, with self-cantering devices & Stainless Steel Piston. The main drive of the machine and conveyor drive consist of A/C Motor with synchronized variable A/C Frequency drive.

Online Injectable Vial Inspection Machine

- Type:Pharmaceutical Packaging Machine

- Power:As per the client required Watt (w)

- Capacity:As per the client required Kg/hr

- Control Mode:Automatic

- Material:Stainless steel

- Computerized:Yes

- Voltage:As per the client required Watt (w)

- Warranty:1 year

- Delivery Time:4 Week

- Supply Ability:30 Per Week

Automatic Single Nozzle Pickle Filling Machine

Automatic Pickle filling machine which are useful for bottle and high weight pet pebbles filling for Mango, Lemon, Mix pickle suitable for bottle filling machine and filling equipment is with Hopper and provision of suitable Nozzle is made.

Semi Automatic Shrink Wrapping machine

Semi Automatic shrink wrapping System will be suitable to accept your pack. The machine shall have an output of 3 to 4 packs/minute. The machine shall consist mainly of three sections. Film Wrapping / Sealing Shrink Tunnel.

Fully Automatic Four Head Screw Capper Machine with Cap Elevator

"SHREE BHAGWATI" Automatic Screw Capping Machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine.

Mini Shrink Tunnel

This Mini Shrink Tunnel is our most economical shrink tunnel. Designed for heating circulating type. This shrink tunnels is suitable for PVC film. And the other model SB -4520AL is available in POF films.

Capsule Inspection Belt

This machine is specially designed for 100% visual inspection of capsules from both sides. 100,000 capsules per hour can be inspected on this new GMP model by employing two Operators, thereby reducing inspection cost considerably.

Servo Auger Type VFFS Spices Powder Pouch Packing Machine

Servo Auger Type VFFS Spices Powder Pouch Packing Machine is suitable for all types of spices. it having PLC controlled system.

Semi Automatic Self Adhesive Sticker Labelling Machine

The Semi Automatic/Off Line Vertical Linear Sticker Labelling Machine Model SBSL-60 is a User Friendly Machine. The Machine incorporates latest sophisticated Micro Processor Control Label Dispensing system with user friendly Sensing system for Label and Product. The Machine is suitable for Labelling on Round Jars, Bottles and other round objects with out-put up to 60 Labels per minute depending on product diameter and label size. The Sticker Labelling Machine SBSL-60 has Conveyor and Pressing Belt system identical to Automatic Sticker Labelling Machines for accurate labelling in vertical position, eliminating the inconvenience of manual Product Feeding and Collection of Product in Horizontal type sticker labelling machine. The Inbuilt Automated Label Length detection systems eliminates any need for manually feeding and storing of Label Length data in memory and retrieving the same every time for change of Label Size & re-starting the machine. The System thus saves valuable time, avoiding machine-down time, and helps achieve higher production. Machines having required all basic features as a standard fitment to match the current market needs and also saves cost and time. Machines having required all basic features as a standard fitment to match the current market needs and also saves cost and time.

Rotary Capless Conduction Sealer

Capless Bottle Sealer is used to hermitically seal the containers to avoid pilfering & spillage during transit. Selection of proper sealing machine boost your customers confidence and product credibility.

Multi Head Linear Conduction Sealing Machine - Six Head

Multi Head Linear Conduction Sealing Machine - Six Head is used to hermitically seal the containers to avoid pilfering & spillage during transit. Selection of proper sealing machine boost your customers confidence and product credibility.

Automatic Carton Opening Machine

SB-ACOM high speed box machine adopts automatic program, adapt to different carton size. The machine adopts the cam continuous system, the machine running reliable, stable, and durable. Break through the traditional tape device design, sealing tape Fu Ping, the effect is good, no jump belt. Any self adhesive tape can be used. Forming and sealing feed step less speed control, the speed is adjustable, can save time. Simple operation, easy to adjust, no damage on carton. Carton storage mining horizontal, may at any time to replenish the empty box. Automatic alert to replace tape and replenish the empty box.

Automatic PE Film Shrink Wrapping Machine

This machine is generally used for shrink wrapping for easy opening cans, glass bottles, beer, mineral water, beverage, commodities bottles in group. Hot shrinking packing machine consists of seven actuating motor. Through cooperation between the 7 actuating motor to form the product packed with PVC or PE Shrink film and several bottles as a group come out from the hot shrinking packing machine. This machine adopts 3 feed-in style, bottle feeding can adopts 1 row, 2 row and 3 row. The matched film wrapping, sealing and cutting, hot shrink and cool down can be customized according to product size. The whole machinery absorb Germany advanced technology. We use famous electronic and pneumatic instruments such as Omron, Sick, Norgren, Mitsubish and so on. The finished product is easy for transportation and bulk packing with neat and solid appearance.

Automatic Carton Box Sealing Machine

Comprehensive foreign various sealing machine characteristics on the basis of the latest research and development of successful automatic folding &sealing machine, wide application range, point to the area is small, it can use single unmanned packaging production line can also be connected. Carton to cover, automatic folding into the side cover and rear cover. Quick. Smooth. Beautiful and is widely used in household appliances, textile, food, department stores, pharmaceutical, chemical and other industries.

3000 LPH Soft Drink Production Line For Milk Powder Fresh Milk Yoghurt

- Warranty:1 year

- Voltage:As per the client required Watt (w)

- Drive Type:Other

- Computerized:Yes

- Capacity:As per the client required Kg/hr

- Feature:Beverage, Food, Other

- Dimension (L*W*H):In inches Inch (in)

- Type:Packaging Line

- Delivery Time:12 to 14 Week

- Supply Ability:30 Per Week

Carton Check Weigher

Carton Check Weigher is a PLC based machine and having HMI that allows the operator to modify the operational parameters.

Automatic Bottle Unscramble For Plastic Bottle

Unscramble the plastic bottles, then transfer them to air conveyor in order and in certain direction and feed them into other equipment to carry out next procedure (for example, feed into washing/filling/capping 3 in1 monoblock). It decreases labor intensity and improves productivity, and also prevent from twice pollution caused by hand touching PET bottle.

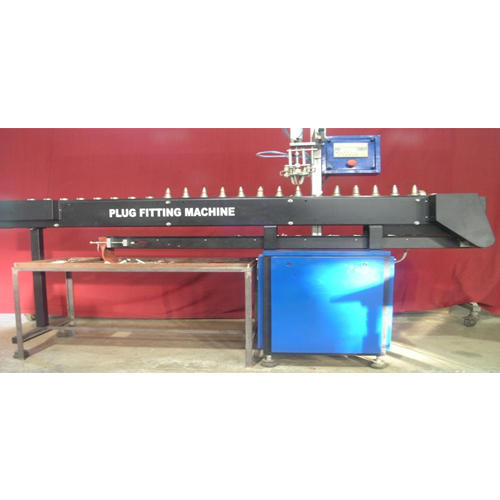

Plug Fitting Machine

Plug Fitting Machine is used to hermitically seal the containers to avoid pilfering & spillage during transit.

Automatic Case Box Opening Machine

The machine automatically perform suction box, forming, under the bottom of the flex. And now taped at the bottom of the complete, professional precision design, the whole machine adopts the motor cam-link.

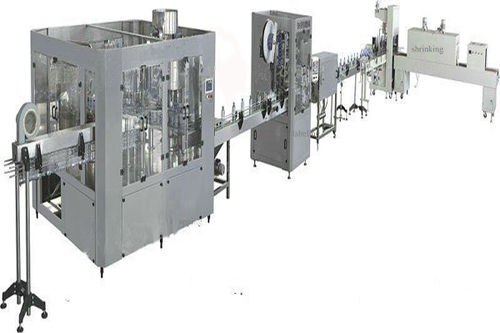

Stainless Steel Carbonated Beverage Bottling Equipment 15000 BPH Energy Saving

The Shree Bhagwati is special in manufacturing the beverage filling production line, such as water filling line, carbonated drink filling line, hot juice filling line, beer filling line etc. We can supply you the whole production line, and also turnkey project.

AUTOMATIC SHRINK WRAPPING MACHINE

Specially designed for packaging production line of beer, beverage, pure water, fruit juice, dairy products, etc. With full automatic functions of bottle transfer and arrange, membrane packing, sealing and cut, shrinkage, cooling and shaping, etc. Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal. The quick seal cooling structure guarantee that the seal has a higher strength even if under high speed production condition. Adopt with PLC automatic program circulation control with stable and reliable performance. The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss. All the transfer system is controlled by frequency changing devices. With stable and smooth transfer speed. Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

Automatic Single Head Wad Inserting Machine

The Automatic Wed inserting Machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

Box Strapping Machine

Box strapping machines are widely used to package all kinds and sizes of boxes including corrugated boxes and PP boxes.The semi automatic strapping machine with top belt driven, powered table is easy to maintain with easily openable table top. Strapping position adjustable by moving sensor position. Box Strapping Machines allow easy loading and unloading of strapping rolls and very carefully and efficiently strap various boxes. The number of boxes strapped, depends on the technical specification and size of the strapping machine. Some strapping equipment consists of electromagnetic clutch transmission for increased strapping speed and has an adjustable cooling time and strap tension and length for better performance.

Plastic Cup Package Industrial Yogurt Making Machine 6 Heads 4000 L/H

As a professional milk and juice production line supplier, we can design, Manufacture, install milk production line and milk plant for producing all kinds of dairy products, such as pure milk, flavored milk, sour milk, yogurt, milk drinking and ice cream, butter, soy milk, tea drinking, energy drinking and so on.

SHRINK TUNNEL

We feel proud to present ourselves as the leading manufacturer, trader and supplier of Shrink Tunnel that can wrap the products of different shapes & sizes conveniently in specified dimensions. This shrink tunnel is utilized for film wrapping electronics product, books, and others. This shrink tunnel is developed under the strict vigilance of our adept professionals utilizing optimal quality components. Our shrink tunnel is demanded for shrinking the shrink films for the tight packaging of bottles, jewel boxes, jars & metal components.

Shrink Sleeve Applicator

Bhagwati Shrink-Sleeve Labelling Machine high speed uses newest shrink technology with MMI and PLC base control panel. The bary centre and base have been accurately design, even use this machine with high speed for long time machine running still very stable and smoothly.Many model with all kind of speed selection from 50/minute to 200/minute and is suitable for wide range; it can be modified according to packages shape. Can meet, all kind of required no matter it is for cap or bottle. The machine is suitable for Pharmaceutical, food industries; it can be for health-food, medicines, Juices, Milk, Drinks, etc.

Automatic Juice Production Line

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays juice to rinse bottle inwall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

Bottle Feeding /Bottle Unscramble

The bottle unscramble is a rotary table to feed the bottles to the filling machine. The material is stainless steel 304.

Automatic Multi Head Aluminium Foil Sealing Machine

The series of wide-mouth bottle sealing machine is a new generation of self-sealing machine developed by my division in accordance with market demand. With the design of combining light, electricity and gas together, it has many advantages, compact structure, beautiful appearance, pretty and firm seal, high efficiency, easy operation and maintenance. It is widely used in sealing a variety of plastic bottles with film and aluminium foil, such as food, pharmaceutical, chemical, cosmetics and other industries, especially suitable for sealing large-diameter polyester bottle. The machine has these functions, moisture-proof, leak-proof, extending product shelf-life, as well as the role of anti-theft and anti-counterfeiting.

PE Film Shrink Wrapping Machine

Shrink packaging machine cannot only be solely used, but used simultaneously with other equipment to form packaging production line. It can automatically array, aggregate and align PET beverage bottle or other similar articles, then package it with shrinking film, finally produce finished products after shrinking by heating, cooling and forming. The packaged product is firmly bound with excellent appearance, which can be opened conveniently. Therefore, it is widely used in industries such as foodstuff, medicine, chemical and other light industrial products.

Air Cooled Induction Cap Sealer

Air Cooled Induction Cap Sealer is used to hermitically seal the containers to avoid pilfering & spillage during transit. Selection of proper sealing machine boost your customers confidence and product credibility.

Online Bottle Neck Trimming Machine

- Control System:PLC Control

- Power:As per the client required Watt (w)

- Color:Other

- Automatic Grade:Automatic

- Material:Stainless steel

- Auxiliary Packaging Machine Type:Other

- Weight (kg):In Kgs Kilograms (kg)

- Dimension (L*W*H):In inches Inch (in)

- Supply Ability:30 Per Week

- Delivery Time:4 to 6 Week

Online Product Check Weigher

Online Product Check Weigher is a PLC based machine and having HMI that allows the operator to modify the operational parameters.

6000 BPH 500 ML Automatic Pure Water Production Line With Reverse Osmosis System

The Shree Bhagwati is specialized in the design, research and development, production and sales of food and beverage machinery and equipment.

Sainless Steel Soft Drink Production Line For Yoghurt Milk 5000 L/H

As a professional milk and juice production line supplier, we can design, Manufacture, install milk production line and milk plant for producing all kinds of dairy products, such as pure milk, flavored milk, sour milk, yogurt, milk drinking and ice cream, butter, soy milk, tea drinking, energy drinking and so on.

Pure Water Easy Operate Soft Drink Production Line

This Complete Mineral Water Bottling Plant is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery.Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Automatic 4 Head Servo PLC Base Viscous Juice Filling Machine

SERVO + PLC BASE AUTOMATIC 4 HEAD VISCOUS LIQUID FILLING MACHINE

Automatic 6 Head Viscous Sauce Filling Machine

Automatic 6 Head Viscous Sauce Filling Machine

Automatic 8 Head Volumetric Liquid Filling Line

Automatic 8 Head Volumetric Liquid Filling Line

Automatic 2 head Volumetric Filling Machine

Automatic 2 head volumetric filling machine

Linear Bottle Washing Machine - 150

Automatic Linear Tunnel Type Bottle Washing Machine

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS