Powder Filling MachineWe are one of the best manufacturer and supplier of industrial grade Powder Filling Machine that are commonly used in the packaging line of the various industries such as food, beverage, pharma, chemical and other for the safe and efficient filing of free flowing powdered materials into plastic and glass bottles in calculated amounts. They are provided with a programmable logical control panel that makes it easier to operate them. Powder Filling Machine offered by us are available in single as well as dual heads. The inlet hopper fixed within these machineries are coated with a non-sticky and anti-corrosive to prevent surface damages.

|

Capsule Filler Machine

- Delivery Time:10-12 Week

- Supply Ability:30 Per Week

- Dimension (L*W*H):In inches Inch (in)

- Capacity:As per the Client required Kg/hr

- Voltage:As per the client required Volt (v)

- Computerized:Yes

- Type:Pharmaceutical Packaging Machine

- Warranty:1 year

- Material:Stainless steel

- Control Mode:Automatic

High Speed Auger Powder Filling Machine

- Dimension (L*W*H):In inches Inch (in)

- Capacity:Up to 60-80 BPM Kg/hr

- Voltage:440 Volts, 3 Phase, 50 Hertz, 4 Wire System Volt (v)

- Computerized:Yes

- Type:Pharmaceutical Packaging Machine

- Warranty:1 Year

- Material:Stainless Steel

- Control Mode:Automatic

- Delivery Time:3-4 Week

High Speed Dry Syrup Powder Filling Machine

High Speed Dry Syrup Powder Filling Machine is suitable to fill powder into dry syrup bottles. Machine provide production output of 100 bottles per minute and widely uses in pharmaceutical, cosmetic, veterinary, herbal & food industries. .

Dry Syrup Powder Filling Machine

The Shree Bhagwati introduces state-of-art Automatic Dry Syrup Powder Filling Machine for filling of large volume powder into containers. Machine is widely uses in pharmaceutical, cosmetic, veterinary, herbal & food industries.

High Speed Injectable Powder Filling Machine

- Computerized:Yes

- Type:Pharmaceutical Packaging Machine

- Capacity:60 to 240 Vials/Minute Ton/day

- Voltage:As per the client required Watt (w)

- Dimension (L*W*H):In Inches Inch (in)

- Weight (kg):In kgs Kilograms (kg)

- Power:As per the client required Volt (v)

- Control Mode:Automatic

- Delivery Time:4 to 6 Week

- Supply Ability:Depends upon the machine Per Week

Automatic Vial Powder Filling Machine

- Warranty:1 year

- Weight (kg):In Kgs Kilograms (kg)

- Color:Stainless Steel Finished

- Power:As per the client required Volt (v)

- Control Mode:Automatic

- Material:Stainless Steel

- Voltage:As per the client required Watt (w)

- Capacity:Up to 30 to 240 Vials/Minute Kg/hr

- Delivery Time:3 -4 Week

VFFS Machine With Volume Metric Cup Filler for Powder Packing

- Automatic Grade:Automatic

- Voltage:As per the client required Watt (w)

- Type:Filling Machine

- Control System:PLC Control

- Computerized:Yes

- Drive Type:Electric

- Auxiliary Packaging Machine Type:Other

- Warranty:1 year

- Supply Ability:30 Per Week

- Delivery Time:4 to 6 Week

Manual Capsule Filling

- Supply Ability:30 Per Month

- Delivery Time:4-6 Week

- Warranty:1 year

- Capacity:300 per plate Kg/hr

- Control Mode:Manual

- Material:stainless steal

- Computerized:Yes

- Type:Capsule Filing Machine

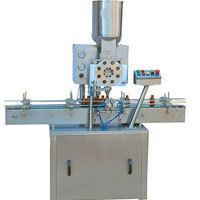

Automatic Single head Powder Filling Machine

Automatic Auger type Powder filling machine is precision built on sturdy welded MS frame completely enclosed in stainless steel sheet and doors are provided to facilitate the servicing of machine. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body.

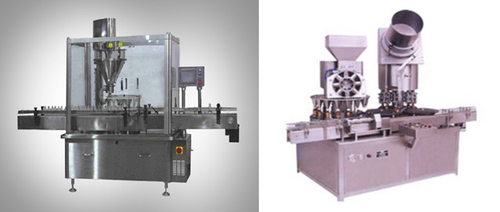

Automatic Two Head Powder Filling Machine

Automatic Auger type Powder filling machine is precision built on sturdy welded MS frame completely enclosed in stainless steel sheet and doors are provided to facilitate the servicing of machine. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body.

SEMI AUTOMATIC SINGLE HEAD AUGER TYPE POWDER FILLING MACHINE

Semi Automatic single head Auger type powder filling machine is Compact Machine, Self Supported on SS Legs with Height Adjustment. The Machine is Precisely Built on Sturdy Welded MS. Frame and Duly cladded with SS. The Powder Filling Unit is Mounted on the Pillars is Supported by Top Plate with Height Adjustments.

Automatic Powder Filling Machine

Operation: The incoming dry bottle sterilized is fed through the in feed Turn Table with suitably guided on the moving Delran flat conveyor belt at the required speed for feeding. There are two separate filling head mounted on machine top plate in the same line. When bottle reaches to the first filling station, it will be held by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of first bottle pneumatic piston goes back and release the first bottle to move on conveyor, by the same time second bottle also moves along with the first bottle in empty condition. In second filling head same operation will be performed but this time second bottle get filled and first bottle moves further for next operation. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value pneumatic system will not going to release the bottle.

Rotary Dry Syrup Powder Filling Machine

The Automatic High Speed Rotary Dry Syrup Powder Filling Machine Model SBPF-120R is suitable for Glass, Plastic, PET, HDPE, and LDPE Bottles with maximum speed of 100 Bottles per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter.

Rotary Monoblock Dry Syrup Powder Filling Machine

The Automatic 12x8 or 16x8 Rotary Monoblock Dry Syrup Powder Filling with Capping Machine is suitable for Glass, Plastic, PET, HDPE, and LDPE Bottles with maximum speed of 100 Bottles per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter.

Auger Powder Filler Machine

Automatic Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling Dry Syrup Powder in bottles.

Powder Filling and Powder Filler Machine

Single Head Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling of Dry Syrup Powder into bottle. The incoming dry bottle (sterilized and siliconised) are fed through the infeed Turn Table with suitably guided on the moving delrin flat conveyor belt at the required speed for feeding. Filling head is mounted on machine top plate. When bottle reaches to the filling station, it will be hold by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets the signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desire amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of bottle pneumatic piston goes back and release the bottle to move on conveyor. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value, pneumatic system will not going to release the bottle.

Semi Auto Auger Filling Machine

This Machine can be fill Any type of dry powder filling e.g. dry syrup,talcum , spices powder, flour etc

Double Head Auger Type Powder Filling Machine

SAF-D-100 Automatic Double Head Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling Dry Syrup Powder in bottles.

Auger Dry Syrup Powder Filling machine

SAF - 60 Automatic Single Head Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling of Dry Syrup Powder in to bottle.

Auger Filling Machines

Backed by a team of prudent professionals, we are involved in manufacturing and offering an immaculate and wide range of Auger Filling Machines from us at very competitive as well as leading market prices in various specifications including customization as per demands. Made from premium quality raw materials,

Auger Powder Filling Machine

Automatic single head filling mounted on machine top plate in the same line. When bottle reaches to the filling position, it will be held by the pneumatic bottle controller. instantly it will be sensed by the bottle sensor as soon as it gets signals from sensor compelling clutch starts to rotate which is mounted on auger shaft. It will fill the desired quantity of powder into the bottle throughout auger, where rotation time is up to that time saved in PLC control. After filling of bottle pneumatic piston goes reverse and release the bottle to move on the conveyor for further next operation. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle gets filled with powder as per set value pneumatic system will not going to release the bottle.

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free