Tablet Press |

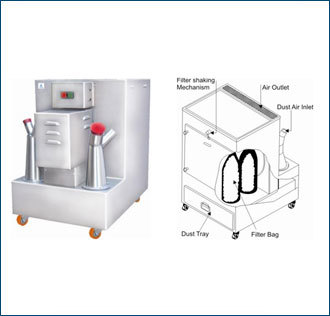

dust collector

This machine is mainly for the pharmaceutical, food, chemical and other industries where dust is generated in the various machine for use, and it s also an ideal cleaning equipment.

Tablet de-duster - Tablet Duster

Our De duster Machine is Highly Versatile, Automatic and Fully Stainless Steel machine.

Dies and Punches

Having an in depth understanding of the pharmaceutical industrys requirements and well equipped to meet the challenges

De dusting and De burring Machine

SBPDB-80 is designed to dislodge deposited dust particles and extract all loose dust from the surface of compressed tablets. Surface dust is a persistent problem with compressed tablets and create problems at sealing either at Blister or Strip packing machine.

dust extractors

We Strongly recommend the use of Dust Extractor Unit with all the Rotary Tabletting Machines in order to control the flying dust generated during the compression of tablets. With the use of this unit, dust in Tabletting Machines is kept to minimum but it is difficult to eliminate it entirely.

Mini Tablet Press, Rotary Tablet Press Machine

Bhagwati Mini Press is a rotary tablet press machine with robust construction that is built as per the GMP derivatives. Mini Press is a state-of-art pharmaceutical equipment from Bhagwati Machines India Pvt. Ltd.

D4 Type Square GMP Model

Manufacturer and supplier of square GMP model single rotary tablet press machine with hygienic features. D4 Type Square GMP Model is also called as double rotary tablet press machine and is commonly used for slugging big tablets. We specialize in designing 8 station rotary tabletting machine, 10 station rotary tabletting machine, 12 station rotary tabletting machine, 16 station rotary tabletting machine, 27 station rotary tabletting machine and 35 station rotary tabletting machines according to the requirement of various pharmaceutical and chemical industries.

High Speed Rotary Tablet Press

It is a high speed rotary tablet press for higher tablet output, suitable for large batch production. Machines is having a square design with full consideration of GMP standards

Single Rotary Tableting Machine

Rotary tableting machine is totally enclosed, i.e. top half of the machine (compression zone) with S.S.hood and acrylic covers and lower half of the machine complete with mat finished S.S.Covers. This reduces the noise level and to & fro flow of dust between compression zone and M/c room. Antivibration mounting provided. Hence no foundation required.

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS