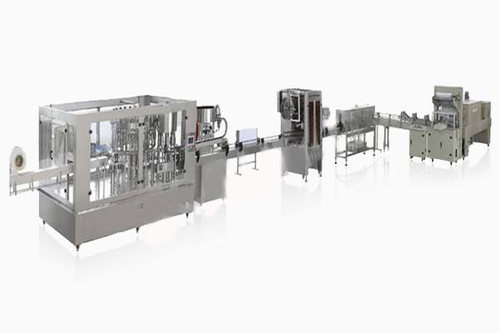

Automatic Filling Production Line For Mineral Water ,Pure Water

Product Details:

- Product Type Automatic Filling Production Line

- General Use For Mineral Water ,Pure Water

- Material Stainless Steel Alloy

- Type Chemical Machining

- Capacity As per the client required Kg/day

- Weight (kg) 15000 Kilograms (kg)

- Computerized Yes

- Click to View more

Automatic Filling Production Line For Mineral Water ,Pure Water Price And Quantity

- INR

- 1 Piece

Automatic Filling Production Line For Mineral Water ,Pure Water Product Specifications

- Yes

- Stainless Steel Finished

- 1 Year

- Chemical Machining

- 15000 Kilograms (kg)

- As per the client required Kg/day

- Other

- PLC Control

- Yes

- For Mineral Water ,Pure Water

- Automatic Filling Production Line

- 2D

- As per the client required Volt (v)

- Yes

- In Inches Inch (in)

- Stainless Steel Alloy

- For Inspection

- Stable Operation High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency Simple Control

Automatic Filling Production Line For Mineral Water ,Pure Water Trade Information

- India

- Cheque Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID) Cash Advance (CA)

- Depends upon the machine Per Week

- 4 to 6 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Packing Only

- Australia Eastern Europe Western Europe Middle East Central America Africa South America Asia North America

- All India

- ISO and CE Certified

Product Description

General description:-

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turn sit over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays juice to rinse bottle in wall.After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the camcan realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and auto rotation. It can finish a whole capping course including catching, pressing, screwing,discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

Technical Specification:-

| Model | SB-01-04 | SB-01-06 | SB-01-08 | SB-01-10 | SB-01-12 | SB-02-12 |

| Number of washing, | 12-12-4 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 |

| Production (600 ml) (B/H) | 2000- | 5000- | 8000- | 12000- | 16000- | 20000- |

| Motor power(kw) | Main | Main | Main | Main | Main | Main |

| Overall dimensions (mm) | 2400- | 2600- | 3100- | 3800- | 4600- | 5450- |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 |

Send Inquiry

Send Inquiry Send SMS

Send SMS