Labeling Machine |

Automatic Ampoule Labelling Machine

Our labeling equipment and machineries have involved ourselves in the manufacturing and labeling process of different industries like food, pharmaceutical and cosmetics that require wide range of labeling like Round, Flat, Oval, Square, Top, security seal as per the requirement. We offer customized labeling at a very low price as compared to services provided all over the country.

Automatic Pallet Labelling Machine

The automatic Top label applicator machine is one of the most users friendly. The Machine incorporated with latest SERVO or sophisticated Micro Processor Control Label dispensing system with user friendly Sensing system for Label and Product. It is suitable for sticker labeling on Products and other flat surface container. It is capability of labeling is up to 300 Products per minute depending on products diameter and label size. Our model - 60 / 120 /150 /250/ 300/ 400 /600 products per minute depends on application and systems.

Automatic Flat Bottle Labeling Machine

Our top labeling equipment and machineries have involved ourselves in the manufacturing and labeling process of different industries like food, pharmaceutical and cosmetics that require wide range of labeling like Round, Flat, Oval, Square, Top, security seal as per the requirement. We offer customized labeling at a very low price as compared to services provided all over the country.

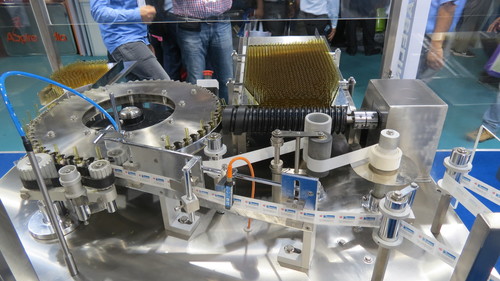

Automatic Rotary Sticker Labeling Machine

Our Self-adhesive Sticker Labeling Machine has its own unique single point like synchronized speed control system and Flexible multiple drive application provides. The bottle labelling machine has Inbuilt Automated Label Length detection systems that eliminates the need for manually feeding and storing of Label Length data in memory and retrieving the same every time for change of label size & re-starting the machine. This in turn saves valuable time, avoiding machine-down time, and helps achieve higher production

High Speed wet Glue Labeling Machine

A/C Frequency Drive for speed control. All exposed parts of the unit are S.S, hard chromed or SS cladded to ensure long life and resistance against corrosion.

Stand Alone Label Applicator

Stand Alone label applicators are useful when higher volumes and Labelling on conveyor lines are needed. A sensor detects the product as it comes down the conveyor and triggers the application of the label at the proper time. Product handling must be tightly controlled to ensure accurate label placement.

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS