Industrial Machinery |

Automatic Bin Washing Machine

It is widely used in such industries as pharmaceutical, chemical industry, food, dairy products, etc It is suitable for cleaning various types of vessels Its structural performance has reached the advanced level of similar international products

Roller Compactor

- Supply Ability:30 Per Week

- Delivery Time:6-8 Week

- Computerized:Yes

- Capacity:As per the Client required Kg/hr

- Color:stainless steel

- Control Mode:Automatic

- Voltage:As per the client required Volt (v)

- Warranty:1 year

- Type:Pharmaceutical Packaging Machine

- Power:As per the client required Volt (v)

Agitated Nutsche Filter Dryer

Agitated Nutsche Filter Dryer is a recent innovation in the filtration technique. It is extensively used in dyes, paints, pesticides and fine chemical industries. Safety requirement and environmental concerns due to solvent evaporation lead to development of this type of filter, where the filtration and drying under vacuum pressure can be carried out in a closed vessel.

Process Reactors Stainless Steel Chemical Reactor

- Delivery Time:4-6 Week

- Supply Ability:30 Per Week

- Motor:AC Motor

- Mixer Type:Homogenizer

- Capacity:As per the client required Kg/hr

- Computerized:Yes

- PLC Control:Yes

- Feature:Vacuum Resistant Vessel, Vacuum Pump, Hydraulic System, High Speed, Automatic Alarming, Digital Time

- Packaging Material:Plastic

- Material:Stainless Steel

Shrink Wrapping Machine

We are engaged in manufacturing and supplying a wide range of Manual Shrink Wrap Machine that is appreciated by the clients for high quality standards. Manufactured using quality raw material, this Wrapping Machines is used for wrapping, stretching and overlapping. These are also considered perfect for pilfer proof, tamper evident all round packing for unit as well as bulk packaging. Having variable speed conveyor drive and electronic temperature controller, these machines are appreciated for offering excellent shrink packaging.

600L Stainless Steel Storage Tanks Three Layer Cooling And Heating Tank

- Delivery Time:4 to 6 Week

- Supply Ability:Depends upon the machine Per Week

- Computerized:Yes

- Color:Stainless Steel Finished

- Capacity:600 LTR Kg/day

- Control System:PLC Control

- Feature:High Performance, ECO Friendly, Simple Control, Low Noise, Lower Energy Consumption, High Efficiency, Stable Operation

- QC System:For Inspection

- Touch Screen:Yes

- Warranty:1 Year

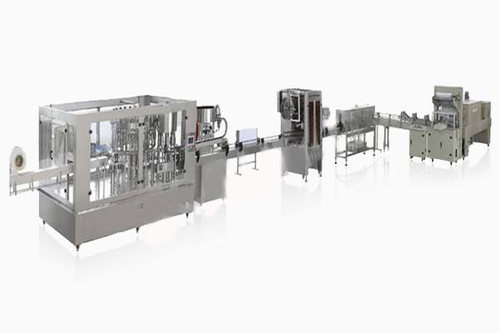

Automatic Washing ,Filling And Capping Machine For Flavoured Milk

Flavored milk bottle filling machine adopts bottle neck holding transmission technology to realize fully automatic,rinsing,filling and capping.Most elements of the electrical system employ foreign advanced products.Each machine element that contacts with the material is made of high quality stainless steel.They obtain the advantages of good abrasive resistance,high stability ,low failure rate,etc.The quality of the equipment reaches the international advanced level

Water 3-IN-1 Bottles Washing Filling And Sealing Machine

Automatic washing, filling and capping three in one filling equipment is one high precision and speed liquid filling machine, product design adopts bottle-neck block technology, not only avoid bottle-neck second pollution, but also can produce different bottle shape filling in one machine. Greatly improve the equipment usage scope. Production capacity from 3000 BPH to 3600BPM can be choose by customer. Main-frame machine adopts frequency conversion timing motor, convenience adjustment speed within throughput.

15kw Stainless Steel Water Storage Tank For Liquid Water Production Line

This tank can be used as liquid storage tank, temporary storage tank, water storage tank and so on.It is suitable for food, dairy products, fruit juice beverage, pharmaceutical and chemical and biological engineering.

Automatic Shrink Wrapping Machine

Backed by a team of diligent and dexterous professionals, we are able to manufacture and supply a complete range High Speed Shrink Wrappers. These machines are quality tested by our experts on various grounds of the industry. Our wrappers are known for their high performance, simpler operations, extended service life, resistance against corrosion & abrasion, and low maintenance. The High Speed Shrink Wrappers machine finds their application in various heavy duty industries for packaging different materials.

High Speed Stainless Steel Tank SS Water Storage Tank Tempreture Control

This equipment is to material efficiently under mixing, pressing and cutting by the high speed rotation of the impeller in the bottom,which is especially applicable for the mixture of sugar,starch,milk powder,egg powder products with the emulsifying agent ,stabilizing agent and thickening agent,usually used in the mixing flow of formula milk powder, acidophilus milk, varius drinks ,ice cream,egg roll and waffles.

Double Layer Tank Material Stainless Steel Tank SS Storage Tank For Juice

Mainly applicable for storaging and mixing of all kinds of liquid products like: dairy products, juice, beer and brew, chemistry liquid , and biology engineering products, etc.

Automatic Filling Production Line For Mineral Water ,Pure Water

Automatic Filling Production Line is very versatile, Fully Automatic, PLC touch Screen based and useful for Mineral water and pure Water

1000 LTR Round SS 304 Stainless Steel Tank For Cooling Storage Fresh Milk

Mainly used for cooling and storage for fresh milk, also can be used to cooling or storage for other liquid product. The cooling tank is the key equipment for the mechanical milking system in the dairy farms. Also widely used in the manual milking farm and milk collection centers, and milk production plants, which can keep the fresh milk at best state and prevent the bacterial growing.

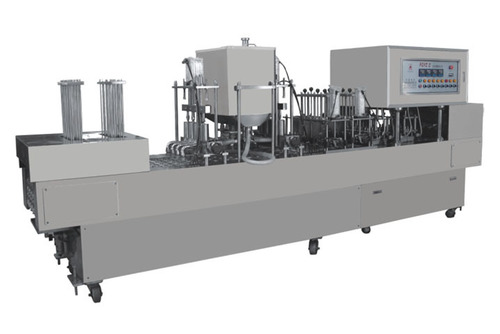

Linear Type Yougourt Cup Filling And Sealing Machine

Automatic cup filling sealing machine is widely used to the food industry, such as jelly, juice, water, yoghurt etc. It can loading cups, filling product into cups, sealing cups by roll film/precut film and finished output automatically. The product contact parts made of stainless steel, which is produced in strict accordance with the food industry hygiene standards; Plastic tray and odd shaped trays, can be customized as requirement

Automatic Robot Palletizing System

Palletizing robot is mainly for packaging application design, is a small, can be integrated in the compact packaging machinery, and can meet your all requirements in reach distance and payload. Structure is simple, easy maintenance and repair; Main components parts less, less accessories, so the maintenance cost is low; Manipulator stacker crane can be installed in the narrow space, can effective use; All the control in the control cabinet screen operation, operation is very simple. Can be all-weather operation, equipped with the machine hand can cover the work of many workers, thus can save each year hundreds of thousands of human resources costs, workers to increase!

|

|

Send Inquiry

Send Inquiry Send SMS

Send SMS