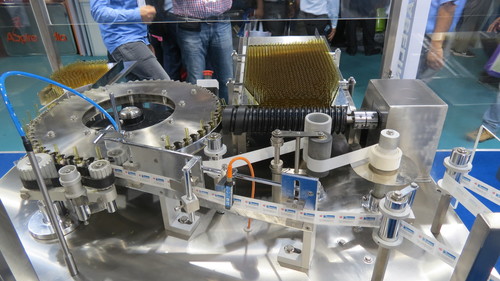

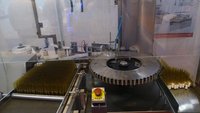

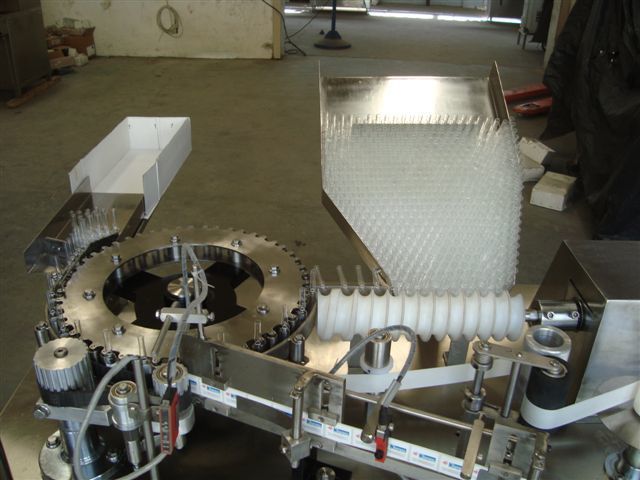

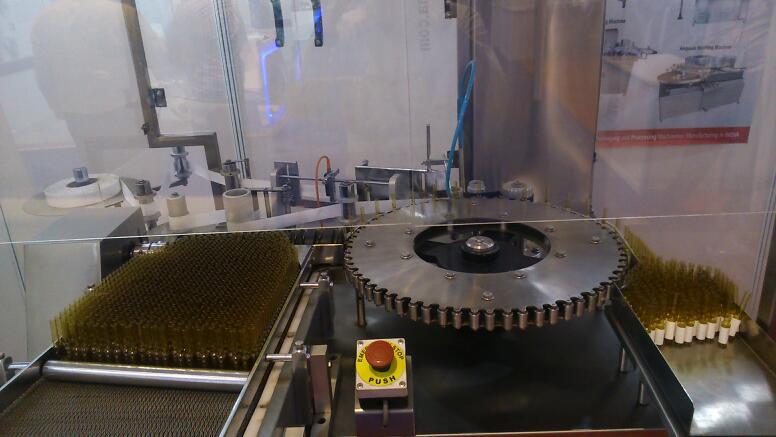

Automatic Ampoule Labelling Machine

Product Details:

Automatic Ampoule Labelling Machine Price And Quantity

- 1 Piece

- 300000-1000000 INR

Automatic Ampoule Labelling Machine Trade Information

- Cash Against Delivery (CAD) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 30 Piece Per Month

- 4-6 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Packing Only

- South America Western Europe Middle East Central America Africa Asia Eastern Europe North America Australia

- All India

- CE & ISO Certified

Product Description

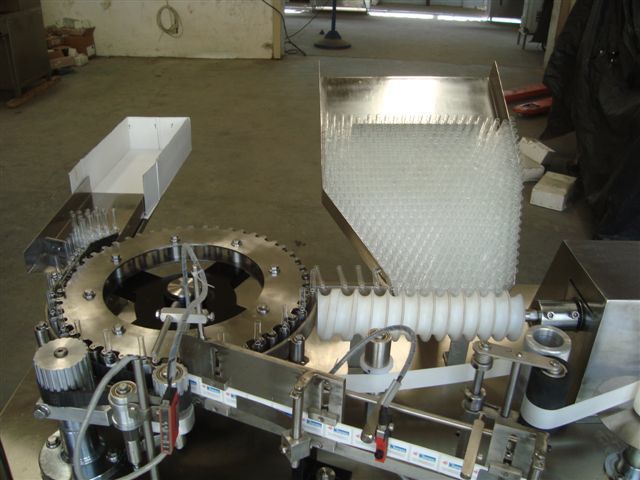

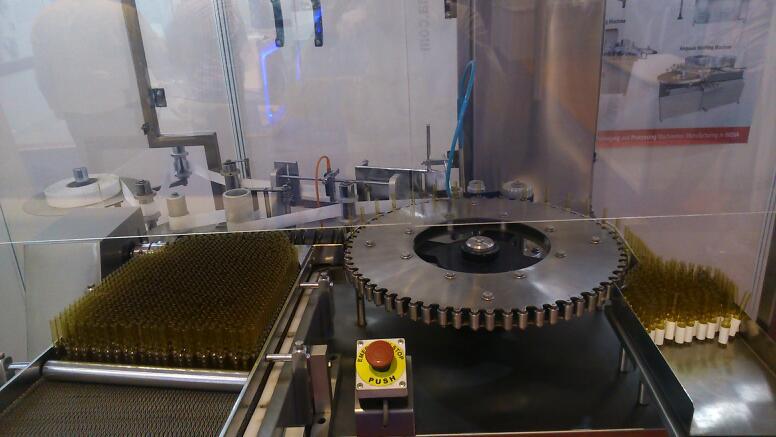

SPECIFICATION OF THE EQUIPMENT MACHINES BASICS

| PARTICULAR | SPECIFICATION |

| Machine Name | Automatic Rotary Ampoule Sticker Labeling Machine |

| Model | Servo Based Machine |

| Production Speed | Upto 100 Containers per Minute (Speed Depends up on the length of label and diameter of product and Operator Skills). |

| Suitable for Products | Glass Ampoule |

| Application | Labeling on Straight Surface |

| Labels Requirement | Self Adhesive Sticker Labels in Roll Form having consistence 3 mm gaps between the 2 labels. |

| Label Material | Self Adhesive Paper Labels |

| Label Roll Outer Diameter | Maximum 300 mm |

| Label Core ID | 75 mm |

| Label Dispensing Accuracy | +1 mm |

| Working Height | 700 mm (+/-50 mm) |

| Machine Weight | Approx 300 Kgs |

| Machine Dimension | Approx 6 (L) x 6(W) x 8 (H) in Feet |

MACHINES MATERIAL OF CONSTRUCTION

| PARTICULAR | SPECIFICATION |

| Machine Main Base Frame | Stainless Steel 304 Pipe Structure |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Star wheel | Stainless steel with Teflon/stainless steel roller |

| Feed worm | Teflon |

| Tray for in feed | Stainless Steel with chain type conveyor |

| Tray for outf eed | Stainless Steel |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | Zinc / Hard Chrome / Blackening |

| Wrapping Belt | End Less Sponge Coated Wrapping Belt |

| Bottle Separation / Spacing Unit | Teflon Feed worm |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |

OPTIONAL FEATURE

- Label Roll Empty Machine Stop System with Alarm.

- Missing Label in Roll Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed ranges available.

- Toughened Glass or Acrylic Safety Cabinet for Machine.

- Tower Light showing the machine status / operation.

- Colour or Mono Touch Screen with PLC for machine operation and showing various error messages and information onisplay.

- Special Sensing system for checking missing label on product.

- Low Compressed Air Machine Stop with Alarm system for pneumatically o- operated coding system.

- Vision System for checking Barcode,presence or absence of Coding or pharma code on labels.

- Vision System with OCR system for checking coding on labels.

- Online pneumatically operated product rejection system.

- Poly carbonate Enclosure in Stainless steel Profile.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free