Liquid Filling Machine for Jar, Tin 1 to 20 ltr

Product Details:

X

Liquid Filling Machine for Jar, Tin 1 to 20 ltr Price And Quantity

- INR

- 1 Piece

Liquid Filling Machine for Jar, Tin 1 to 20 ltr Trade Information

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 30 Piece Per Month

- 6 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Packing Only

- Australia South America Middle East Africa Central America Western Europe Asia Eastern Europe North America

- All India

- CE & ISO Certified

Product Description

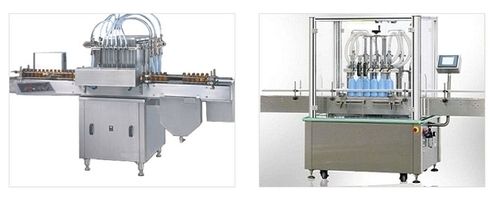

Electronic Liquid Filling Machine

Description :

The Semi Automatic Electronic Liquid Filling Machine (e-fill-1HS) is compact and highly efficient machine with elegant look. This multifunction multi featured machine meets the custom requirements of Bulk filling in Jars or Cans with no restriction of liquid characteristics. The machine has its own pumping system to fill the programmed liquid in Jars. The flow of liquid is measured and converted in to electronic signals being controlled by the PLC base circuit. No mechanical adjustments are required to set different fill volumes with different sizes of containers. i.e. No change part is required.

|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| * Speed depends upon Fill Volume, Neck diameter of Bottle, Viscosity, Specific gravity and Forming Characteristic of liquid. | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

Enter Buying Requirement Details

Other Products in 'Bottle and Vials Liquid Filling Machine' category

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry Send SMS

Send SMS